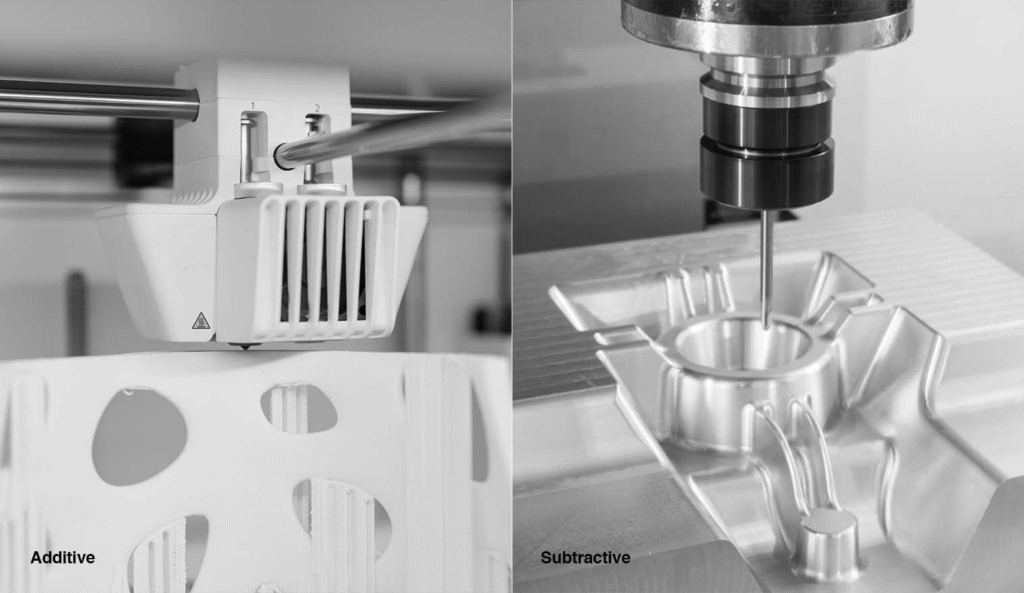

When sourcing plastic components, engineers often compare 3D printing and CNC machining — especially for functional nylon parts. Two of the most capable options are:

- Multi Jet Fusion (MJF): a powder-bed 3D printing process ideal for complex geometries and short-run production.

- CNC machining: a subtractive manufacturing method known for precision, tight tolerances, and broad material compatibility.

So which one is better for your project? Let’s compare them across cost, geometry, finish, speed, and scalability.

🧪 What Is Multi Jet Fusion (MJF)?

MJF uses:

- Nylon powder (PA12, PA11, TPU)

- An inkjet printhead that applies fusing and detailing agents

- An infrared lamp that sinters the entire layer in a single pass

This process builds parts quickly, without support structures, and produces strong, isotropic parts with a fine matte finish.

🔧 What Is CNC Machining?

CNC machining cuts away material from a solid block using:

- Computer-controlled tools (mills, lathes, routers)

- A wide range of thermoplastics (e.g., Delrin, Nylon 6, PEEK)

CNC offers tight tolerances and high precision, but is limited by tool access and fixture design — especially for internal features or undercuts.

⚖️ MJF vs CNC Machining: Side-by-Side Comparison

| Feature | MJF (Multi Jet Fusion) | CNC Machining |

| Part Geometry | Very complex, organic forms | Simple to moderate geometries |

| Internal Channels | Yes, no support needed | No (requires multi-op machining) |

| Surface Finish | Matte, lightly textured | Smooth to polished (tool dependent) |

| Wall Thickness | Down to ~0.02–0.04 in (0.5–1 mm) | Typically > 0.08 in (2 mm) |

| Strength (XYZ) | Isotropic | Strong, but anisotropic for thin walls |

| Accuracy | ±0.003–0.010 in | ±0.001–0.005 in |

| Lead Time | 2–5 days | 5–15 days |

| Setup Cost | Low (no tooling or fixturing) | High (toolpath + fixture setup) |

| Cost Per Part (low qty) | Lower for complex or nested parts | Lower for simple blocky shapes |

| Cost Per Part (high qty) | Scales well to 10k+ | Efficient with automation |

🧠 When to Choose MJF

MJF is ideal when:

- You need complex geometry or internal features

- You want short lead times without custom tooling

- Part volumes are 10–10,000 units

- You’re iterating on design and need flexibility

- Parts require consistent isotropic strength

💡 When to Choose CNC Machining

CNC is the better option when:

- You need tight tolerances below ±0.002 in

- You require optical or polished surfaces

- The geometry is simple and planar

- You need non-nylon engineering plastics (e.g., PEEK, UHMW, Delrin)

🔄 Hybrid Approach: Print, Then Machine

In some cases, customers combine both:

- Print complex near-net shapes via MJF

- Post-machine critical features (e.g., bearing bores, sealing faces)

This hybrid method can cut costs while maintaining tolerances where they matter.

🏁 Conclusion: MJF vs CNC Machining

| Need This… | Best Choice |

| Complex geometry or internal channels | ✅ MJF |

| Ultra-precise fits or fine threads | ✅ CNC |

| Short lead times and design agility | ✅ MJF |

| Non-nylon high-performance plastics | ✅ CNC |

| Repeatable batches with no tooling | ✅ MJF |

| Highly cosmetic surface finish | ✅ CNC (with polishing) |

🏭 Ready to Compare for Your Project?

RapidMade offers both MJF printing and precision CNC machining — and we help engineers decide which is best based on geometry, volume, material, and speed requirements.

Upload your file and get a side-by-side quote at rapidmade.com